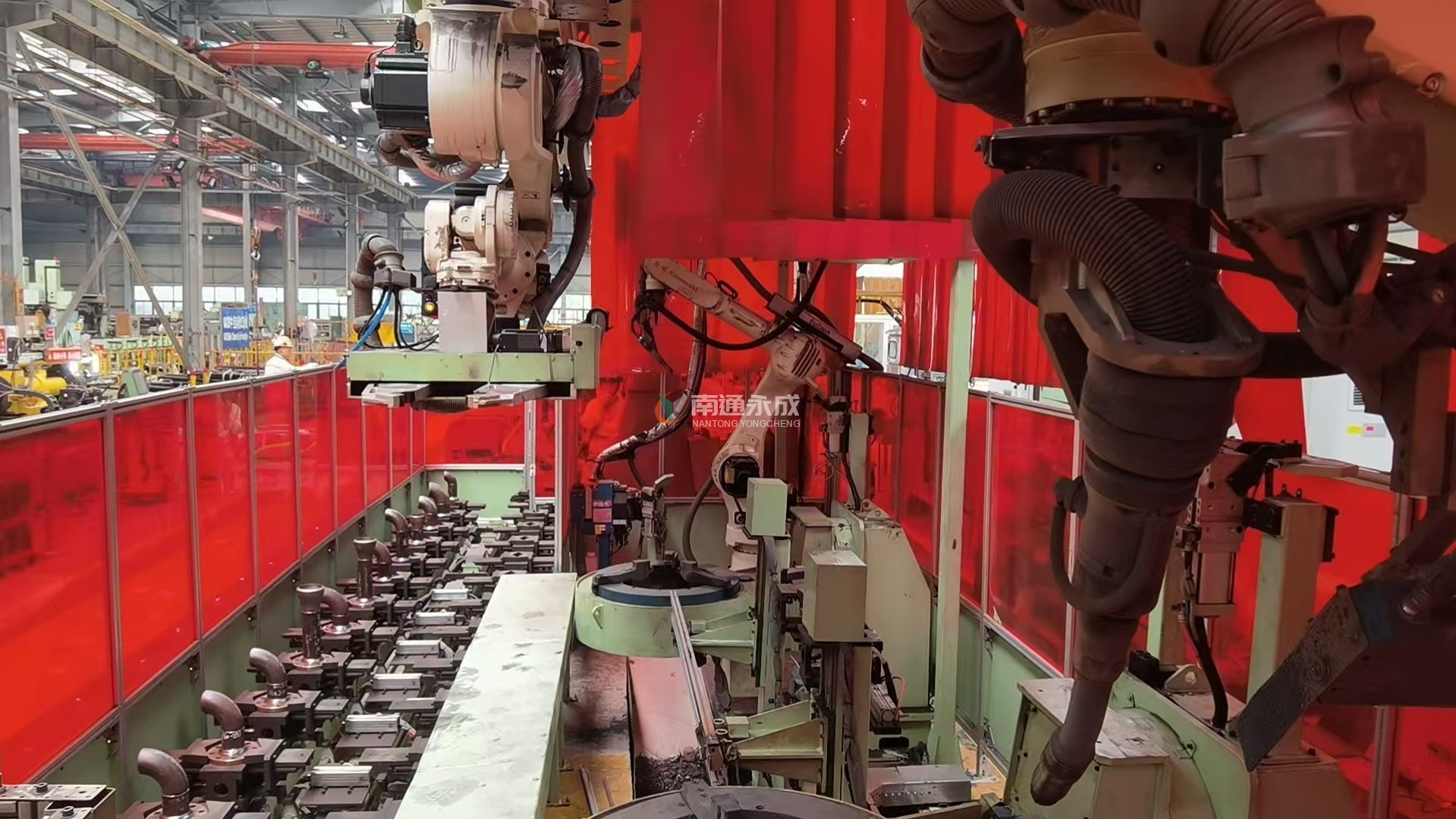

Centralized robot laser welding production line

Product Description

This pipeline is used for automatic welding of short pipes with a cut-off length not exceeding 900mm, butt welds of small vertical pipes, and automatic welding of inner and outer fillet welds of flanges/sockets.

Applicable pipe diameter 65A~125A;

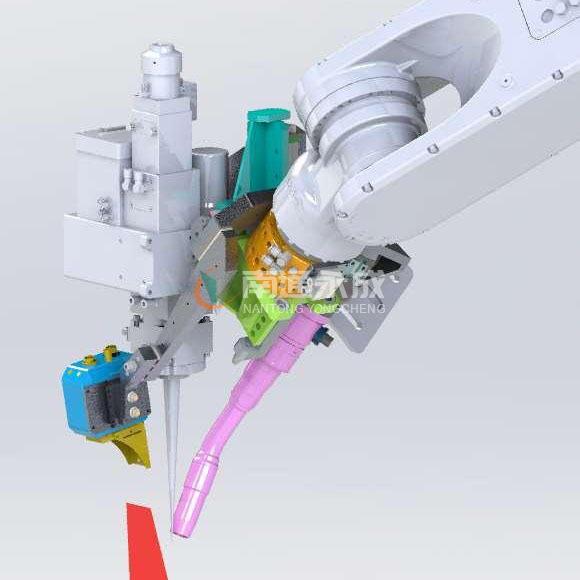

Automatic weld seam tracking function;

Weld seam search function;

Short pipes, small vertical pipes, and metal fittings are assembled and loaded onto the production line. The production line achieves automatic transmission, automatic loading, robot automatic welding, and automatic unloading, forming a flow production line. Each workstation can also be manually operated independently under special circumstances.

Welding process:

Butt welds formed after connecting pipes to pipes, pipes to elbows, and pipes to reducers are welded using solid wire for the root pass, laser + MAG composite welding for filling, and CO2 welding for the cover pass.

Inner and outer annular welds formed after connecting flanges/sockets to pipes are welded using CO2 welding.

Related Products

Online Message

We will contact you within one working day, please pay attention to your email